Machineries

Vertical and Horizontal Conveying System

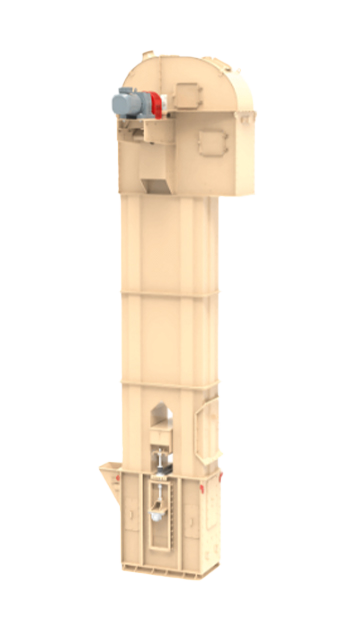

Bucket Elevator

Description: Bucket elevator is the mechanism for conveying bulk, powder and granular materials such as gypsum, calcite, lime, cement etc, vertically.

Aim

The aim of this specification is to describe general design parameters and specification of bucket elevator manufactured by Parget Makina

Scope

Specification scope is limited to description of design details of bucket elevator manufactured by PARGET MAKİNA İMALAT İNŞAAT MÜHENDİSLİK SAN. VE TİC. LTD. ŞTİ

General Description

- Bucket elevator is a mechanism for hauling flowable bulk materials, often powder and granular, vertically.

- A chain, placed between the chain rollers, carries the buckets elevating material from the feeding point until the top.

- Bucket elevators are designed depending on material type and density, conveying distance, capacity and other criteria.

- There are two main designs:

- Belt elevator,

- Chain Bucket Elevator

- Central Chain Type,

- Double Chain type,

- Bucket elevator consists of tension unit, drive unit and intermediate vents.

- Tension and drive units include chain rollers, shaft and bearing houses.

- Buckets are mounted to the tense chain which is placed between rollers of tension unit and drive unit.

| Machine Types | Capacity |

|---|---|

| PM_ECC200 | 16 |

| PM_DAC800 | 22 |

| PM_DAC1000 | 32 |

| PM_DAC1250 | 50 |

| PM_DAC1500 | 71 |

| PM_DAC1750 | 100 |

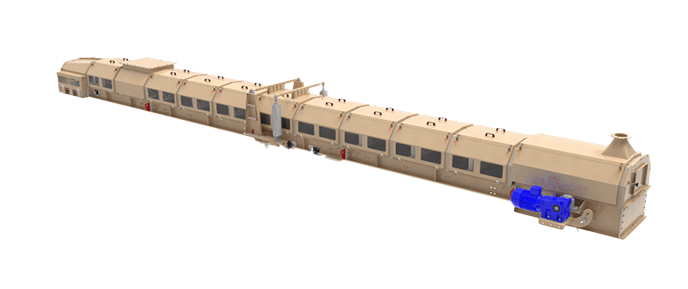

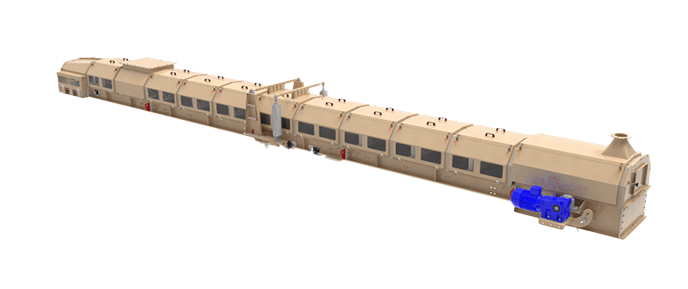

Belt Conveyors

Description: The belt conveyor is used for conveying different kind of materials in horizontal or inclined way on a certain angle positions.

Aim

The aim of the specification is to define general design parameters and specification of the belt conveyor manufactured by Parget Makina.

General Description

The belt conveyor is used for conveying different kind of materials in horizontal or inclined way on a certain angle positions.Belt conveyor can be produced in different kind of models depending on the used area, material properties, capacities, conveying distance.Belt conveyors with the high reliability and low energy consumption are preferred to be used in every area where different materials are being conveyed.

Modified conveyors can be operated with abrasive, corrosive, hot, chemicals, fragile and brittle materials.

Types of the belt conveyor;

- Flat type

- Trough type

- V type

The basic elements of the belt conveyor are: support frame, drive and tensioning stations, carrying idlers, conveyor belt, inlet and outlet, ladder and platform. The elements of the tensioning station are: tensioning drum and bearings. The elements of the drive unite are: drive drum, bearings, geared motor.

In addition, there are maintenance hatches that enable an easy intervention in cases of breakdown.

Belt Conveyor Specifications

The belt conveyor is chosen according to the conveyed material specifications can be PVC, polyurethane, rubber etc. The appropriate width of the belt conveyor prevents material spillage and the inlet width allows the largest parts of the material to pass smoothly. Belt thickness range is 8-16 mm depending on the conveyor design.

| Machine Types | Motor Power (kW) | Capacity (t/day) | Diemensions (distance from feeding to discharge point) |

|---|---|---|---|

| PM-BCV500 | Depends on thecapacity, length and inclination of the machine and product features | Different capacity from 5 t/h until 400 t/h, depending on the product features and customer request. | Different lengths depending on the customer request and the project requirement. |

| PMBCV650 | Depends on thecapacity, length and inclination of the machine and product features | Different capacity from 5 t/h until 400 t/h, depending on the product features and customer request. | Different lengths depending on the customer request and the project requirement. |

| PM-BCV800 | Depends on thecapacity, length and inclination of the machine and product features | Different capacity from 5 t/h until 400 t/h, depending on the product features and customer request. | Different lengths depending on the customer request and the project requirement. |

| PM-BCV1000 | Depends on thecapacity, length and inclination of the machine and product features | Different capacity from 5 t/h until 400 t/h, depending on the product features and customer request. | Different lengths depending on the customer request and the project requirement. |

Weighing Belt Conveyor

Description: Weighing belt conveyor is used for feeding powder and granular materials as continuously weighing within a fixed time period. It is designed depending on the material type to feed, handling capacity and dosing volume. The material is passing through on the belt is weighed in short periods and constantly, thanks to the weight-sensitive platform and high-precision measurable load-cell.

Parget Makina designed weighing belt conveyor is an economical and effective solution for dry dosing systems. It can be used especially for dosing of free-flowing materials with irregular flow and non-free flowing materials (very dry and fine or wet materials)

| Machine Types | Benefits |

|---|---|

| Capacity | WIDE RANGE OF CAPACITY 1 - 80 T/H |

| Weighing Mechanism |

|

| Conveyor Belt |

|

| Drive Unit |

|

| Automation System |

|

| Tip | Capacity Range | Motor Power | A | B | C | H | H1 | L |

|---|---|---|---|---|---|---|---|---|

| PM-WBC500 | 1-10 t/h | 2,2-3 kW | 820 | * | * | 114 | min.650 | * |

| PM-WBC650 | 2-15 t/h | 2,2-5,5 kW | 1000 | * | * | 114 | min.710 | * |

| PM-WBC800 | 10-30 t/h | 3-5,5 kW | 1150 | * | * | 114 | Min.850 | * |

| PM-WBC1000 | 20-50 t/h | 3-7,5 kW | 1300 | * | * | 114 | Min.940 | * |

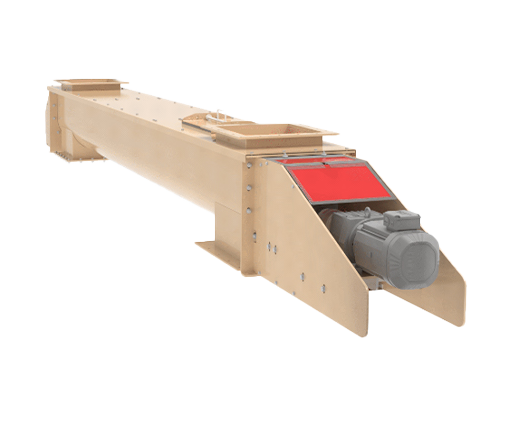

Screw Conveyor

Aim

The aim of this specification is to describe general design parameters and specification of screw conveyor, manufactured by Parget Makina.

General Description

Screw Conveyor is used for horizontal transportation or slightly inclined transportation of bulk materials, often powder or granular. It is designed in required length and capacity depending on the field of use, characteristics of conveyed material, required capacity, conveying distance and inclination. Rotation of helical screw drives material from inlet point to outlet with fixed or variable speed.

Design parameters of screw conveyor:

- Capacity (ton/hour)

- Diameter of rotor

- Diameter of rotor pipe

- Screw pitch and screw thickness

- Inclination

- Rotation speed

- Inputted filling level

- Screw Lengt

- Type of conveyed material

Screw conveyor is designed considering foresaid parameters. Suitable motor is seleceted according to filling level of 40-45%. Maximum rotation speed is 70 rmp. However, per customer request it is possible to exceed the rotation speed.

| Machine Types | Capacity (m3/h) |

|---|---|

| PM_SCU250 | 12 |

| PM_SCU300 | 23 |

| PM_SCU350 | 34 |

| PM_SCU400 | 47 |

| PM_SCU450 | 70 |

| PM_SCU500 | 11 |

Screw Conveyor

Standard design of screw conveyor can be: Tube type (O type): outer pipe is made of seamless drawn steel pipe with front welded-on detachable flanges. Helical screws with variable pitches are welded to the center pipe (screw inside pipe) and are installed on floating bearings of the drive and end plates. Due to use of floating bearings it is possible to prevent deformation that can occur because of the temperature change.

Depending on customers’ request, maintenance openings, inlets, outlets and bolt connected cover, ensuring fast material discharge in urgent situations, can be added in different quantity. Trough screw (U type): trough, made of bent steel sheet (Hardox, S235JR), is welded and/ or bolt connected with main parts. Helical screws with variable pitches are welded to the center pipe (screw inside pipe) and are installed on bearings of drive and end plates.

Due to use of floating bearings it is possible to prevent deformation that can occur because of temperature change. Depending on customer request, maintenance openings, inlets and outlets and bolt connected cover, ensuring fast material discharge in urgent situations, can be added in different quantity. Additionally, special designs can be provided according to customer requests and different sectors. Depending on characteristics of conveyed materials, screw conveyors can be made completely of S235JR, stainless steel or HARDOX.