Machineries

Packing and Packaging Sytems

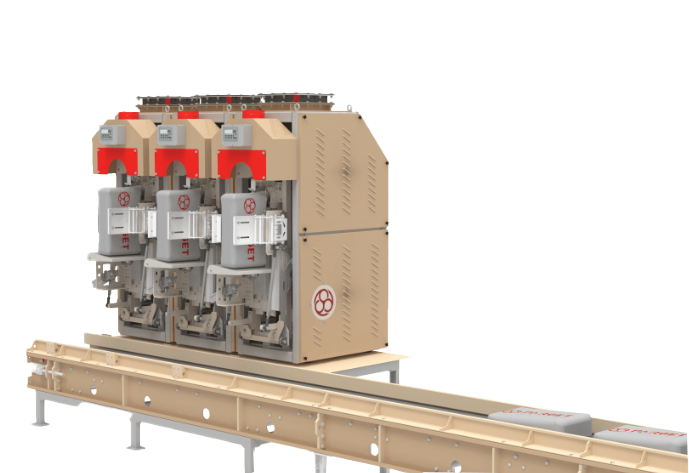

1.Linear Packing machine

Linear Packing Machine is used for precise weighing and automatic packaging of granular or crystallized powder products with free flowing feature. In addition to its linear weighing feature, it is generally suitable for weighing materials with stable granular structure.

Linear packing machines, which offer the possibility of filling valve bags made of Kraft or PP (Polypropylene) material in the range of 20-50 kg at the desired capacity depending on customer demand, provide the ability to weigh products in certain micron ranges with a tolerance level of ± 2%, depending on the process conditions.

Advantages

- Capability of working with different products, bag types and bag sizes.

- Easy calibration and integration to the automation system.

- Minimum damaged bags.

- Automatic and precise measurement.

- Filling group that can be easily changed in case of wear.

- Wear-resistant rotor lining option.

- By the help of compressed air applied to the filling rotor; fast and sensitive filling by preventing material jamming in the filling nozzle.

- Possibility to fill bags starting from 15 kg to 50 kg

| Machine Types | Motor Power (kW) |

|---|---|

| PM_LPM1 | 5-8 |

Features are given only for a single linear packing machine

Working Principle

The linear packing machine precisely weighs the material fed to the scroll-rotor group connected to the drive unit and ensures that it is packaged. The rotor blades inside the scroll made of casting material facilitates the fluidity of the material. The material fed to the rotor is transmitted to the filling nozzle by means of the rotating rotor blades, fills to bags connected to filling nozzle automatically. There is a bag fixing cylinder on the top of the filling nozzle and a switch on the bottom that gives a signal when the bag is attached to the nozzle. The bag fixing cylinder works in integration with the switch and moves downwards when the bag is connected, ensuring that the bag is in the filling position.To facilitate the filling of the bag and to prevent possible nozzle clogging, preliminary air is supplied during the first start-up.

The guillotine flap, which can move precisely in three stages as open, semi-open and closed, provides flow control of the material. Thanks to the step that is activated at certain periods depending on the process conditions, high precision filling is ensured. In the first stage, the material coming from the rotor is filled while the damper is in the open position.In the semi-open stage, the rotor continues to operate, but the amount of material fed to the filling unit through the flap is reduced. In the sensitive filling stage, when the guillotineflap comes to the closed position, the motor and accordingly the filling group stop. The material accumulated in the distance from the filling nozzle tip to the guillotine flap is filled into the bag with the help of air. Thus, sensitive filling is ensured and the machine is made ready for the next filling process by preventing the solidification of the material waiting in the machine.

By the help of hood located at the top of the machine, the dust that occurs during filling operation is absorbed. Thus, the process quality is increased, especially during filling.At the bottom of the filling unit, there is a powder pouring chute that ensures the removal of the material overflowing with air from the filling nozzle. The pendulum flap located at the end of the powder discharge chute provides the exit of the dust accumulation. In addition, the material collected in the dust discharge channel can be transferred to the dust collection bunker (optional).

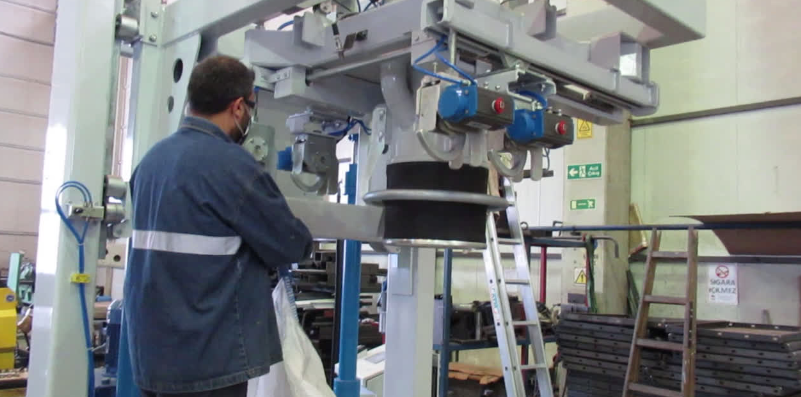

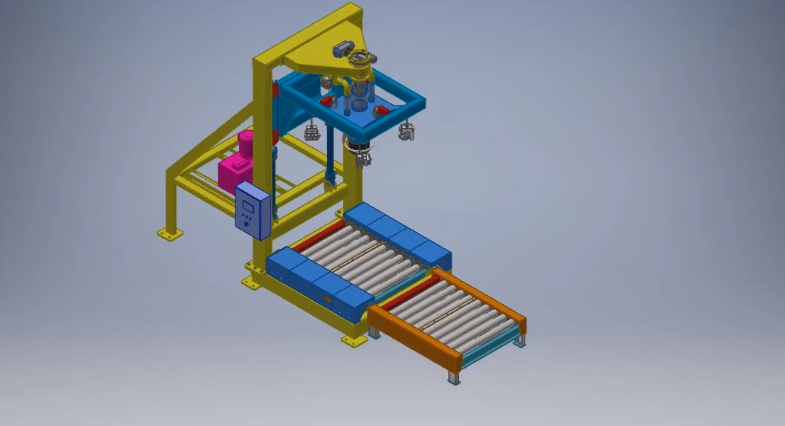

2.Big Bag Filling Machine

Big-Bag filling machine realizes the filling of powder and granular materials to Big-Bags by means of PLC control.Pallet magazine, film sheet applicator and rotate table are using as auxiliary equipment while the filling process as optional.Depends on the customer request, different type of properties can add to the machine like automatic big bag hanging mechanisim and semi- mobile system etc.customer demand, provide the ability to weigh products in certain micron ranges with a tolerance level of ± 2%, depending on the process conditions.

Capacity: max. 20 bags/ hour *

Bag dimensions: max: 150x150x150 cm - min. 85x85x85 cm

Accuracy: ±%1

Weighing system: Loadcell

Filling time: Approx. 3-5 min (grapple-filling-second big bag grapple duration) **

*The limit for system’s working capacity and time is operator’s speed

**The capacity and filling time can show a change according to operator speed and material features.

Technical Features:

Max. Capacity: 9-11 bags/hour*

Dimension: 2250 x 3935 x 1940 mm

Bag dimension - Filling rate: max. 150x150x150 cm / min. 85x85x85 cm - 500-2000 kg

Accuracy: ±%1

Loadcell: 3 pcs / (located on the big bag filling machine)

Weigh module: Siwarex- Siemens

Panel: Simatic-Siemens

Filling time: approx. 3-5 min (grapple-filling-second big bag grapple duration) **

Big-bag filling machine will be manufactured with hydraulic system, level and position sensors mounted onto, single opening, automatic filling, bag blowing and big-bag release system.

*The limit for system’s working capacity and time is operator’s speed.

**The capacity and filling time can show a change according to operator speed and material features.

Working Principle

Firstly, the pallet tier that is positioned on the pallet magazine by forklift is fed to big bag filling machine. (Pallet feeding can be by manually) Bag mouth holders are movable and the back side of the holders are moving to the operator. Thus, operator can hold the bags easily. By the value of filling which is entered to the system, material which is received by hopper transported directly and thus automatic filling process is realized. Dusty air which composed inside of the bag is expelled via outer wall. When filling process is over, grapples are automatically open, and bag is sent down onto the rolling conveyor automatically. New bag attached and process is repeated. Big bag with pallet which is completed the filling process is stocked on the roller conveyor. If required, the pallet is turned by rotate table and conveyed by the forklift

Options

1.Automatic big bag hanging mechanisim

2.Semi mobile design

3.Pallet maganize

4.Film sheet applicator

5.Rotate table

6.Second densification device