Product

Machineries

Dosing Weigthting and Mixing System

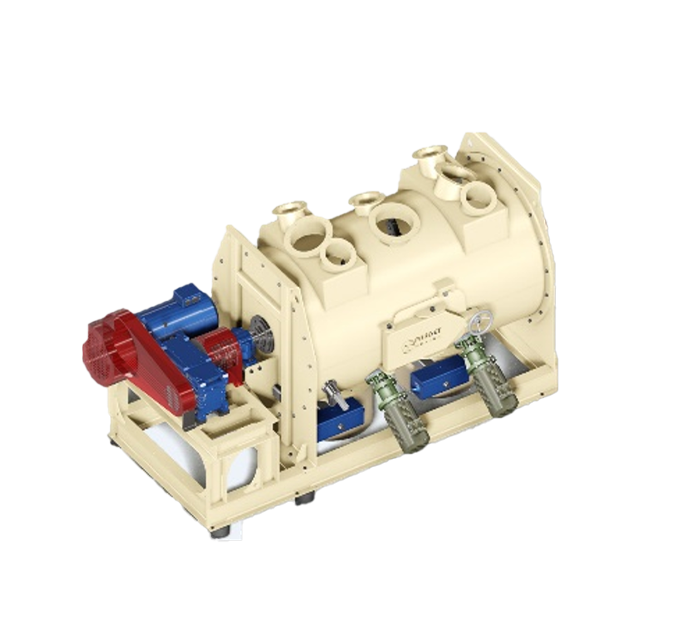

Dry Batch type Horizantal Single Shaft Mixers offered reflect the high quality of solutions originating from profound know-hoe in process technology, from individual turning of machine components in compliance with the mixed product, as well as from the selection of specific materials in conjunction with state-of-the-art manufacturing technologies.

The dry batch mixer works according to the principle of centrifuging and conveying effectively and is used for homogeneous mixing of differenet types of materials (such as base material and additives). It is designed in desired size and capacity depending on usage area, material properties to be fed and material capacity.

Dry Mortar Technologies Machinery

Single Shaft with discharge flaps type

Advantages

- Hig Capacity range (empty volume from 500 till 12000 lt/batch)

- Maximum mixing homogeneity

- Excellent reproducibility of batches

- Robust design

- Safety and easy operate

- Adjustable , replaceable mixing tools

- Maintenance-friendly design

- Reliable reproducibility of the mix quality

Working Principle

The dry batch mixer is a machine used to obtain homogeneous mixing by means of the mixing blades on the rotor shaft by the rotation of the rotor shaft by the drive group.

The mixer discharfge flap operates by means of a pneumatic cylinder bearing at both ends. The flap is opened and closed by the movent of the cylinder . After the meterial is mixed homogeneously, the cover is opened by the bacj movement of the piston and the material is poured.

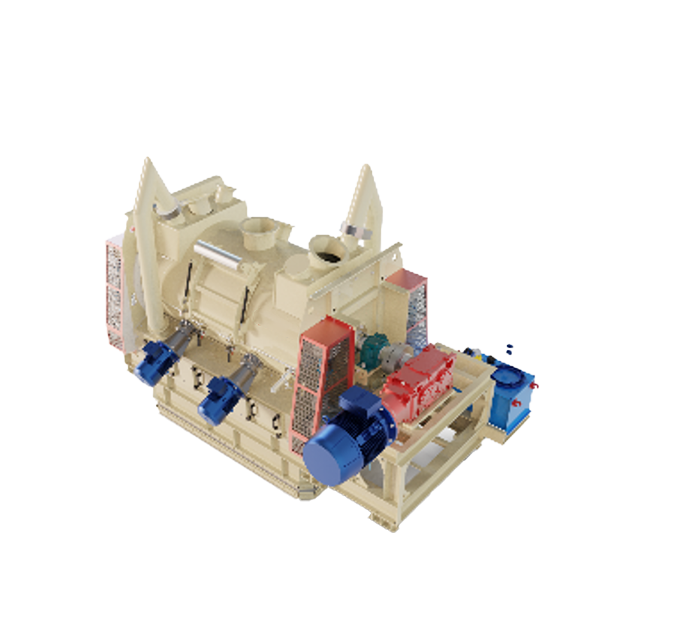

Single Shaft with complete opening type

Advantages

- Hig Capacity range (empty volume from 500 till 12000 lt/batch)

- Maximum mixing homogeneity

- Excellent reproducibilty of batches

- Robust design

- Safety and easy operate

- Short mixing type

- Adjustable, replaceable mixing tools

- No product deterioration or damage

- Easy cleaning and access to all internal partsa of the mixer

- Residual material < 0.1% due to 90 opening angle

Working Principle

The dry batch mixer is a machine used to obtain homogeneous mixing by means of the mixing blades and side mixing blades on the rotor shaft by the rotation of the rotor shaft by the drive group.

The construction of this type of mixer with an outler opening along the entire lenght the druym ensures almost residue-free discharge of the product in the shortest possible time

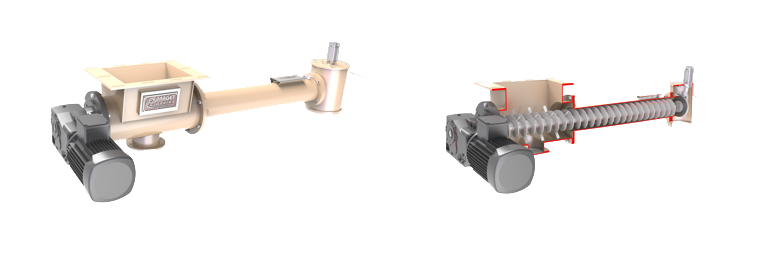

Microdosing Screw Conveyors

They are used for dosing chemical and micro additivies in a very small quantity in order to get high accuracy in micro weighing bin, durring dry mortor production. Dimension depends on capacity and formulation of dry mortar. High accuracy obtained by special screew and pneumatic shut-off valve. Ohter sizes of equipment are alsı available.

Dosing Weighing Bin

AIM

The aim of the specification is to define general design parameters anf specification of the weighing bin manufactured by Parget Makina.

General Description

Weighing bins are used for the precise weighing of bulk solids. Custom designed weighing bins are adapted to the specific powder characteristics, usage area and capacity.

Weighing bin provides precise and high accuracy dosing of up to 8 diffrent chemical materials. Load cells placed on bin in three different points provide blanced and sensitive dosing. Due to integrated automated system the dosing and weighing process are carried out automatically.

Weighing bin is connected to the local filter that provides intake of the air pressure that may occur during the working process. This process prevents the formation of vacuum in the machine and thus can be obtained more precise weighing.

The air bellows in the bin that are filled with constant compressed air provide the equicvalent blance of the machine.

Weighing System

The material is fed into the weighing bin throught the various stocking equipment silo, bin etc.The weighing is carried out throught the load cells taht placed on the three points of the bin body. The required amount of the material is weighed automatically buy automatic system PLC.After the dosing the weighing system automatically resets and get ready for new dosing. This process is carried out by the amount of materials that fed to the weighing bin and continues until all required doses of the prescription have been dosed to the weighed bin. After the dosing all materials in required weight the materials are dischargng through the valve that mounted to the bin.